Dynamic Air Technology strongly believes that the base is the most important part of the air handling unit. Without a good a good foundation, the unit will not operate properly.

Dynamic Air Technology strongly believes that the base is the most important part of the air handling unit. Without a good a good foundation, the unit will not operate properly.

For this reason, Dynamic Air Technology standard is a structural steel "C" channel base. Cross sections under heavy components such as fans and coils are also structural steel channels. Tubing (2"x2") is welded across channel bases at a minimum 24" centers for the best support for the floor. The base can also be made from structural aluminum to reduce weight, and even structural stainless steel to further protect against rust.

DAT's standard unit construction is G-90 galvanized steel. For double wall construction, a G-90 galvanized steel solid or perforated liner will be used to cover up the insulation. If required the unit casing can be built using 304 or 316 type stainles steel and even 100% aluminum for weight issues.

DAT's standard unit construction is G-90 galvanized steel. For double wall construction, a G-90 galvanized steel solid or perforated liner will be used to cover up the insulation. If required the unit casing can be built using 304 or 316 type stainles steel and even 100% aluminum for weight issues.

Depending on the location of the unit, roofs are either constructed for indoor or outdoor use. Outdoor roofs are double pitched from center so that in case of rain, water will not rest on top of the unit. Indoor units have a flat roofs making the unit easier to access and look sharper.

DAT uses a standard fiberglass insulation. In special cases, foam and thermal break options can be provided for those operating in very low temperatures.

Standard water tank and drain pan construction is made of 304 stainelss steel. Drain pans are built with a double slope to ensure no standing water. Drain connection is a standard NPT with the size of the pipe dependant on the drain pan size.

Standard water tank and drain pan construction is made of 304 stainelss steel. Drain pans are built with a double slope to ensure no standing water. Drain connection is a standard NPT with the size of the pipe dependant on the drain pan size.

Water tanks are positioned under the indirect and direct cooling selctions. Water tanks are completely welded to ensure no leakage of water from corners. A submersible pump is usually placed inside the water tank and connected with a series of copper pipe or PVC to distribute water evenly over the indirect and direct sections. A dump valve, intake valve, and a water float valve are installed to ensure proper operation.

Dynamic Air Technology has a wide variety of two component polyurethane paint to satisfy the needs of the customer. After the unit is assembled, the surface is prepared by sanding and cleaning. Once cleaned, the unit heads over to our paint booth. DAT has polyurethane paint rated for 1,000, 3,000, and 5,500 hour salt spray test. When requested, an 8,000 hour sal spray test primer is applied prior to painting.

Dynamic Air Technology has a wide variety of two component polyurethane paint to satisfy the needs of the customer. After the unit is assembled, the surface is prepared by sanding and cleaning. Once cleaned, the unit heads over to our paint booth. DAT has polyurethane paint rated for 1,000, 3,000, and 5,500 hour salt spray test. When requested, an 8,000 hour sal spray test primer is applied prior to painting.

Standard color is stone gray. If a customer prefers a different color paint, a paint chip can be sent to match the color.

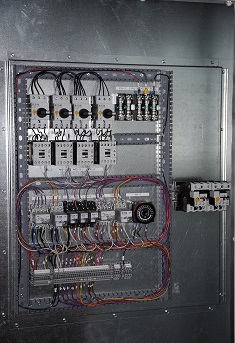

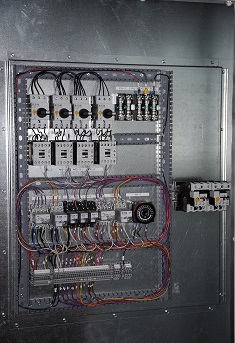

Electrical controls required to operate the unit are assembled at the DAT plant. The standard is a NEMA 3R weatherproof enclosure externally mounted on the unit to house the electrical components. Other rated enclosures are possible including explostion proof enclosures and components.

Electrical controls required to operate the unit are assembled at the DAT plant. The standard is a NEMA 3R weatherproof enclosure externally mounted on the unit to house the electrical components. Other rated enclosures are possible including explostion proof enclosures and components.

Some of these components may include a disconnect switch, step-down transformer, fuses, circuit breakers, motor overload protection, contactors, and control relays. Indirect/direct cooling units will also include a timer, to set a dump cycle, and a freeze stat, to stop the unit from operating at freezing conditions.

Dynamic Air Technology strongly believes that the base is the most important part of the air handling unit. Without a good a good foundation, the unit will not operate properly.

Dynamic Air Technology strongly believes that the base is the most important part of the air handling unit. Without a good a good foundation, the unit will not operate properly.